Why IPCMMS Mechanized Maintenance System?

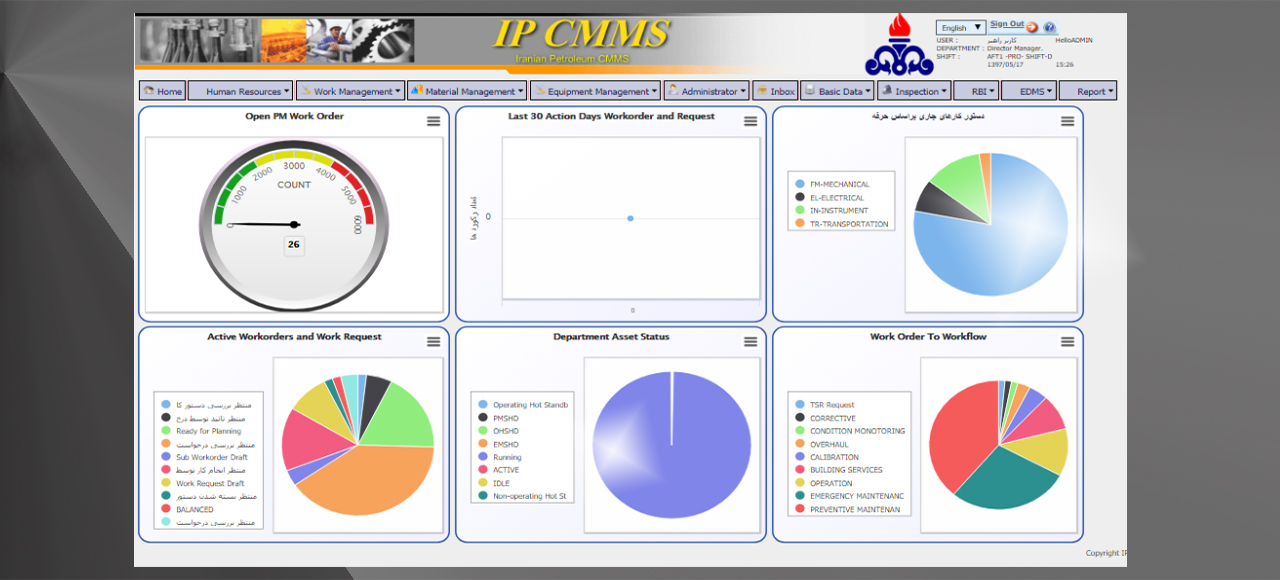

IPCMMS Net software is the result of years of experience in implementing CMMS and meets all the requirements in the field of maintenance and enables equipment management to improve the quality of equipment repairs and reduce maintenance costs in a tangible way. N.

This software has been prepared and designed with RM approach and using global standards and best practices. The main basis of this software is the ISO 14224: 2006 standard and the use of the experiences and expertise of more than 100 experts from the Ministry of Oil and its subsidiaries.

The software features of this CMMS such as good speed, web hosting, very simple and user-friendly user interface have made the software significantly efficient and usable.

Ability to localize the software in the shortest possible time, multilingual software, diverse and beautiful user environments, links to comprehensive systems of property, personnel and oil products, support for various maintenance modules and provide software in one format Integrated software system includes documentation of installation, implementation, training, data collection, etc. are prominent features of IPCMMS software.

Targets

Reduce maintenance costs

Easy and fast access to equipment information

Protection of national capital and physical assets

Increase safety, environmental protection and occupational health

Provide easy and fast access to maintenance actions

Assist in decision making by receiving accurate and up-to-date information

Asset Management system and equipment management (ISO14224 standard)

Work Order Management System

Human resource management system

Preventive Maintenance system and management

Maintenance, repair and inspection scheduling system

System Management

Stock Management system and warehouse management

Data collection module

Contract Management System and Management

Calibration Management System

Inspection Management system and management

Predictive Maintenance System and Management Predictive Maintenance Based

Purchase Management system and materials

Workflow designer and workflow tracking system

System and management of repair workshops Workshop Management

System and project management and overhaul Project Management

Repair cost management

EDMS repair archive system and documents

Management based on RCM reliability

RBI risk-based inspection management

Management of KPI repair indicators